General

technical data of the

locomotive:

| Builder: |

Baldwin

Locomotive Works, Philadelphia, Pennsylvania |

| Model/Type: |

DRS 6-4-660,

N° 72926 |

| Date of delivery: |

28th of dec.1946 |

| Road numbers: |

040DA29 than

A1A-A1A 62029 |

| Diesel power

[kW/HP]: |

560/750 |

| Locomotive power

[kW]: |

398 |

| Maximum starting

tractive

effort [kN]: |

208 |

| Maximum safe

speed

[km/h]: |

96 than 80 |

| Weight in working

order [t]: |

109,5 |

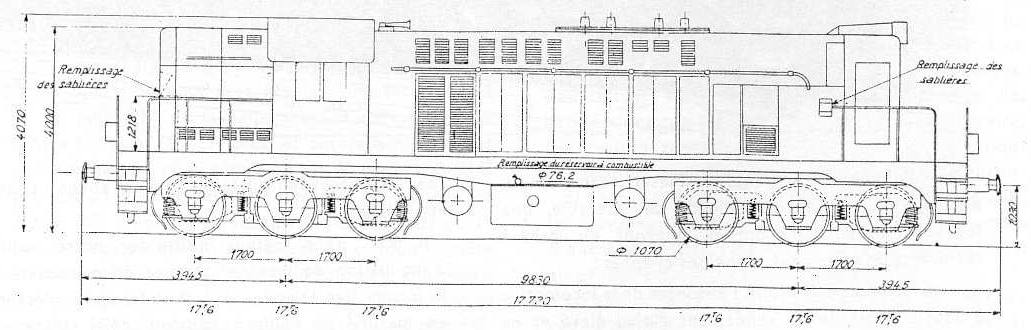

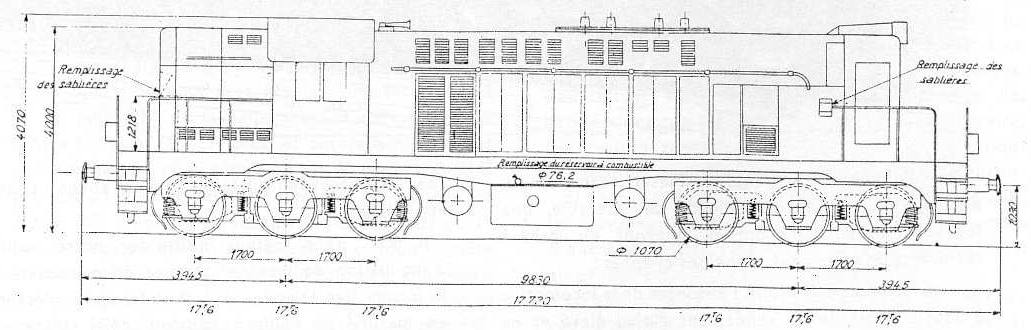

| Total length [m]: |

17,72 |

| On-board voltage

[V]: |

130 |

General

characteristics

of the prime mover:

| Builder: |

Baldwin

Locomotive Works, Philadelphia, Pennsylvania |

| Model/Type: |

DeLaVergne type

606 NA |

| Cycle: |

4 stroke |

| Air supply: |

Naturally

Aspirated |

| Max.Power [kW] @

engine speed [rev/min]: |

560 @ 625 |

| Specific fuel

consumption

[g/kWh]: |

233 |

| Fuel consommation

@ Pmax [l/h]: |

174 |

| Max.Torque [Nm]: |

8550 |

| Break Mean Eff.

Pressure [bar]: |

5,5 |

| Linear piston speed [m/s]: |

8,21 |

| Number of

cylinders [-]: |

6 in line |

| Bore

* Stroke [mm*mm]: |

324*394 |

| Displacement

(cylinder

/ total) [l]: |

32,48 / 194,9 |

| Total mass of

engine [kg]: |

12644 |

| Cooling method: |

water |

| Starting method: |

electric using

the main generator |

| Injection system: |

1 Bosch injector

et

1 high pressure Bosch

pump for each cylinder |

Diesel prime

mover builder plate:

General view:

Builder plate:

Short

presentation:

This

locomotive is certainly the most impressive of our collection. Its

prime mover and its fantastic sound is the reason for the high interest

for it among the

railfans in France.

The

100 A1A-A1A 62000 (former 040DA) were built between april 1946 and

august 1947 from the Baldwin Locomotive Works in Eddystone,

in the suburb of

Philadelphia in Pennsylvania and delivered to the french state railways

SNCF, in the

framework of the Lend/lease programm which goal was to rebuild Western

Europe

after WW2. The well known Mikado 141R were also part of this

plan.

For

the Baldwin Builder, which was specialized since decades in

the

construction of steam locomotives in the USA (like ALCO and LIMA), this

series is paradoxically its first large production experience for

diesel locomotives. The precedent series for the domestic

market

were by far smaller.

First

registered under the number 040DA (figure "4" for 4 drive axles, "D"

for Diesel and "A" because these locomotives were the first diesel

series in France) they were

renamed "62000" in 1962 after the renumbering of the entire SNCF

locomotives fleet.

After

having used for 2 ot its 3 prototypes (only!) of diesel-electric

locomotives diesel engines from european conception (one was a CoCo

numbered "58501", completed in 1925, powered by a V12 2-cycle from

Morrison-Knudsen which was air started, the other was a

BB numbered "61000", completed in 1929, powered by an in-line turbocharged 6 cylinder with

260l displacement and built by Krupp in Essen in Germany), Baldwin, who

bought 1931 one of the most famous US-based reciprocating machine

builder from that time, the De La Vergne company, decided to equip its

3d prototype in 1936 (a BB numbered "62000", yes!)

with an 6 cylinder engine from this company. This engine would

constitute the base for any future locomotives produced by Baldwin.

No diesel engines from other builder would find any entry into the

Eddystone production from then on.

Our

diesel-electric locomotives is equipped

with a slow-running (max 625rpm), in-line

6 cylinder, 4-stroke,

water cooled naturally

aspirated Diesel

engine from

the 600-series. For each cylinder there is one cylinderhead equipped

with 2 intake and 2 exhaust valves. These are controlled

through a

unique camshaft using two push rods and two levers. In the original

engine called "VO", the combustion chamber was integrally built in the

cylinderhead,

a design which caused a lot of

troubles that could not be corrected very soon because of the

restrictions of the War Production Board (who prohibited design changes

during WW2). The 600-series engine is a enhancement from the VO engine.

One of the major change involves the combustion process. Therefore the

cylinderhead has been completely redesigned and the VO flat top

piston replaced by a Hesselmann-type piston with open

combustion

chamber principle. Fuel is now direct-injected in the

combustion

chamber using a Bosch high-pressure pump and one injector for each

cylinder.

It

is started by the prime generator which is shortly fed with

current from the batteries. These were first lead batteries, then

cadmium-nickel (for more than 40 years!) and now again lead-acid

batteries (9 of 180Ah capacity).

The

engine drives directly the prime generator, a

double stage

air-compressor from type "CD" (Westinghouse) and the propeller of the

fan

which cools down the water and oil radiators

and the two blowers of the

traction

motors. The exciter and auxiliary generators are driven by

V-belts, like the ventilators for the traction motors are. All these

equipments are delivered by Westinghouse.

Note

that despite its (even

for the US of the 40's) impressive

dimensions, (displacement of 194L that's to say nearly 33L per

cylinder), its engine is only rated at 750HP/492kW

which 660HP/492kW are available for traction.

Beware:

in the US, the builder specifies the power which is available for the

traction and not the power of the sole Diesel engine. At the french

railways (and other act exactly in the same way), it is the opposite:

the diesel engine power is specified without taking into account the

power needed by auxiliary equipment like auxiliary generator,

ventilators of motors and engines, air compressor or excitation, which

reduce the available power for the traction. At Baldwin, the

difference whichever engine it was was about 110 to 125HP (82 to

93kW).

The

engine belongs to the 600 series and is called 606NA because of its 6

cylinders and the Naturally Aspiration. The NA versions were rated from

660HP/492kW to 750HP/560kW. These engines were later turbocharged and

called 606SC. They were rated between 1000HP/746kW and

1325HP/988kW. The biggest versions of the 600 series were (and still

are) the in-line 8 cylinders versions. Generally speaking, the number

of 8 cylinders, naturally aspirated version is limited. These NA

engines were rated at

1000HP/746kW but soon replaced by the 606SC with the same power

output with 2 cylinders less. The 608 engine were later also

supercharged and called 608SC. They could deliver between 1500HP/1119kW

and

1750HP/1305kW power output.

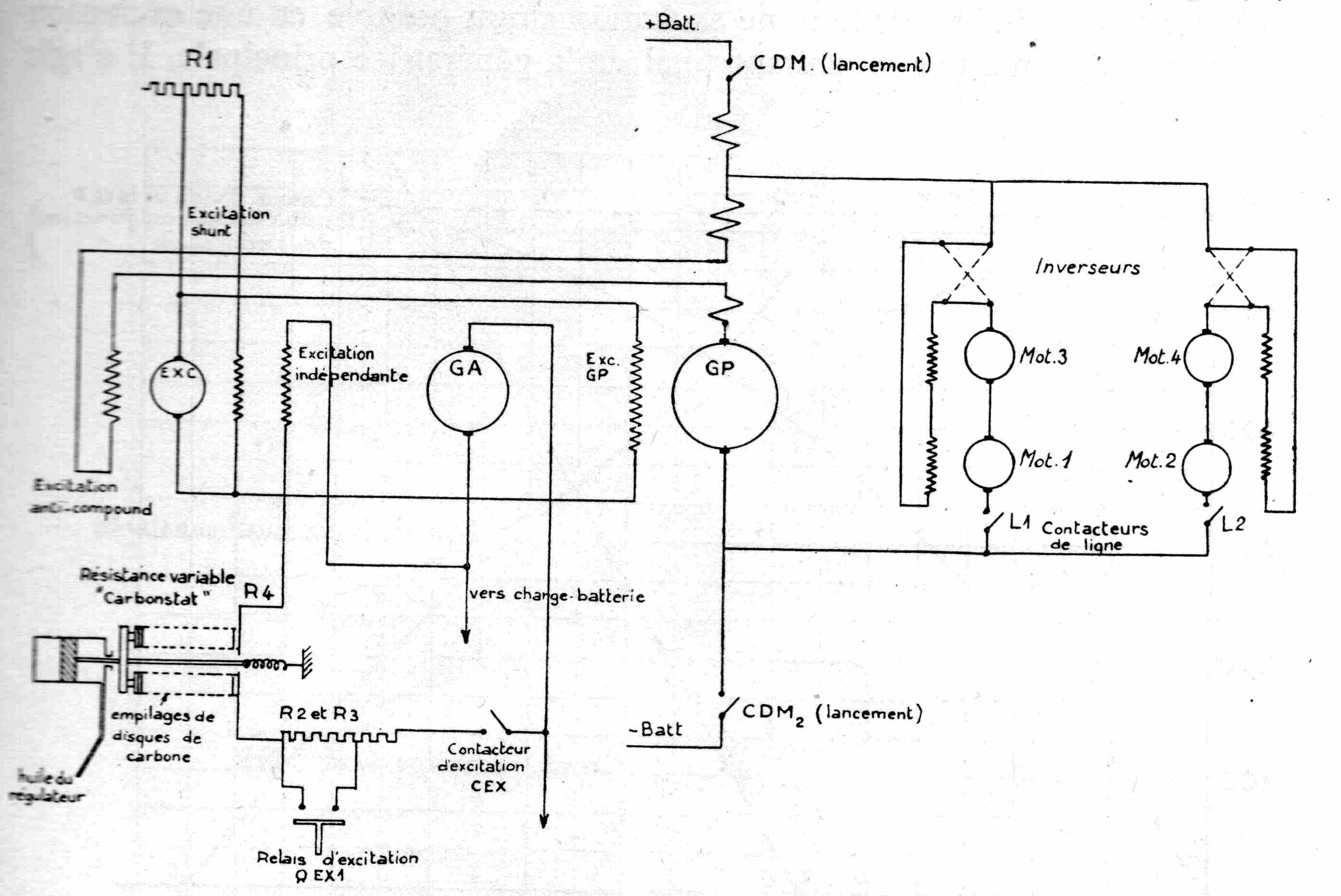

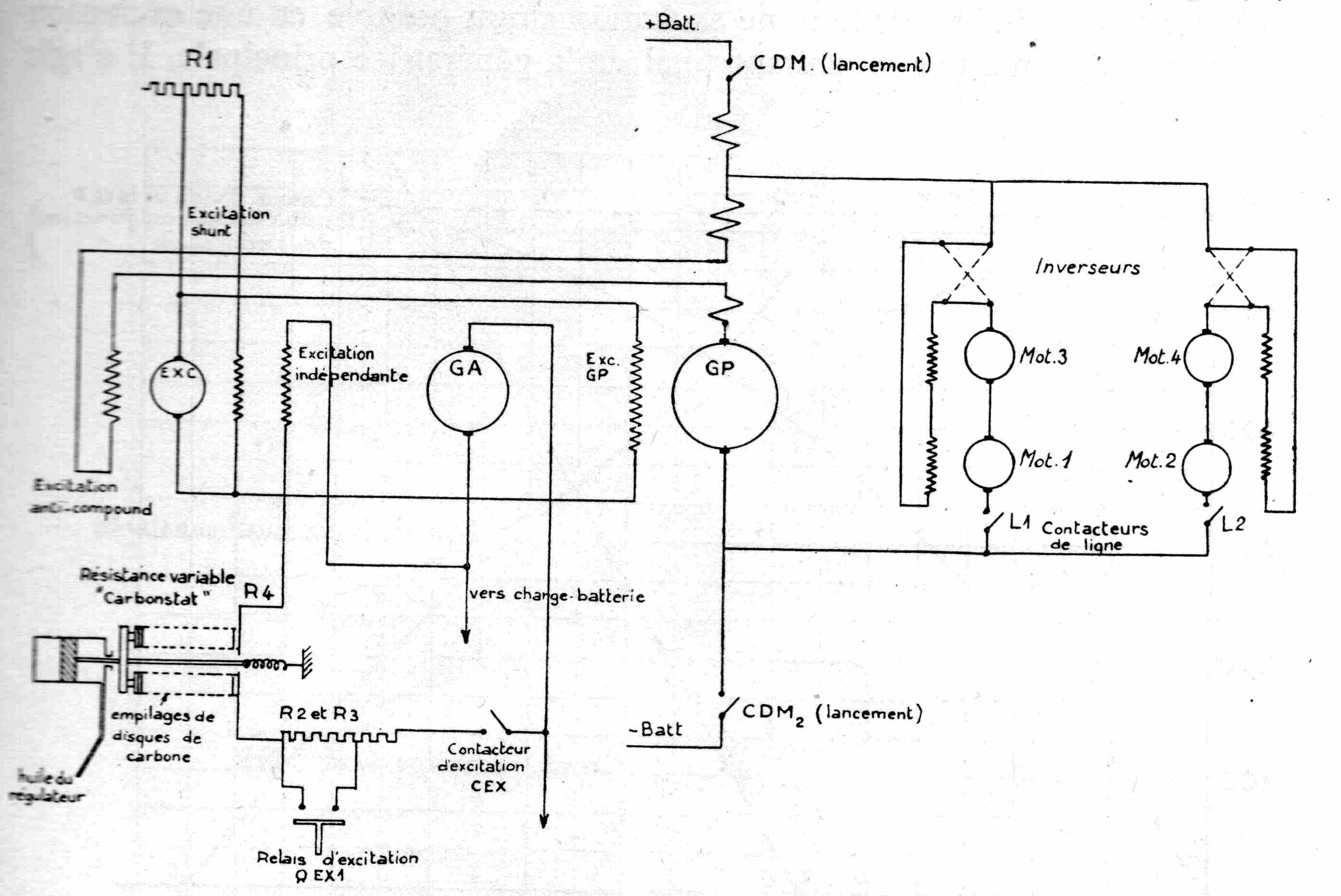

The

prime generator has a separate excitation. This excitation

winding

is fed by an exciter from which the excitation is composed of shunt

(positive), a serial (negative) and a separate winding fed by the

auxiliary generator. The current through this separated winding is

limited by a system called "Carbonstat" (TS31) which purpose is to

avoid

the diesel engine to stall if the torque demand of the generator is too

high. A modification done by the SNCF was to allow the locomotive

engineer to vary directly this current by adding or subtracting

resistors

in this circuit. The driver can now choose the tractive effort at a

given diesel engine speed.

The

brake is an Westinghouse specialty: it is a kind of

a triple

valve. The GE has a similar system. It

is a distributor 6 DKR which can be found as well on the 141R.

The

chassis and the trucks are in cast steel. These trucks were first used

on steamlocomotives or on their tenders and are equiped with 3 axles

and 2 nose-suspended electrical traction motors from type Westinghouse

362 with 4 poles. The 14/68 gearing

allows a maximum safe speed of 96km/h (60mph). Suspension

uses leaf and helix springs and is fully equalized. The connection

between chassis and trucks is also original.

These

locomotives were the first experience of dieselization on a large scale

for the french national railways, more through necessity then by

choice. The reconstruction of France was at that time an absolute

priority.

Very soon, the trucks revealed to be very agressive for the track and

the maximum safe speed has been limited to 80km/h (50mph). Also the

journal boxes need continuously lubrication made by hand (Symington).

This precluded early their use on long distance. So, they were

more and more used only for yard works for example at humps,

especially in the North (coal ore) and the Lorraine (iron ore). On both

sides of

the atlantic the Baldwin excelled on mining regions: Pennsylvania is

the equivalent of the french Lorraine or the german Ruhr regions. They

were very suited to the service on humps where the locomotive pushs

long trains at

a slow and regular speed with high tractive effort. The Westinghouse

electric equipment

was oversized (generator and traction motors were used on

1000HP

locomotives) so that they could withstand high overloads without majour

problems.

Electrical schematic view:

Life at CFTR:

| Last owner before

salvage: |

SNCF |

| Retirement date: |

1982 |

| Acquisition date: |

1983 |

| Current owner: |

CFTR |

| Restoration: |

Currently not running |

| Use at the CFTR: |

Run the train

from depot to the

station and switching at Sans-Soucis |

| Retirement by the

CFTR: |

- |

Our

62029 (Building number 72926 and not 73201 like above picture shows!

This number is that one of the 62086) has been bought in Lens

(North of France) in 1983 by a founding member. It was not too

difficult to repair it as it was just overhauled by the workshop there.

Now, our baldwin is operated regularly to pull

train to the station and switch at Sans-Soucis and every

driver

enjoys it. First of all, the webmaster who drives it, secondly

the

railfans

who take pictures of it and thirdly the oil industry because of its

higher turnover.

In

2014, some difficult work had to be done: a roller bearing of one of

the traction motors was defective and had to be replaced. But it is

like the cathedral of Strasbourg:

you begin here, continue there

and you never stop repairing!

Pictures (CFTR):

Changing

a

traction motor? No problem, we can do that! (Photo

Sébastien Kieffer)

Bibliography and external

links:

- Loco-revue documentary

file;

- SNCF characterstics

file;

- trains miniatures

n°19, mai-juin 1988;

- Voies

Ferrées 78, juillet-août 1993;

- Diesel Locomotives:

the first 50 years, Louis A. Marre, Kalmbach Books, 1995.

- The Diesel Builders,

Vol.3, John F. Kirkland, Interurban Press, 1994.

- Diesels from Eddystone: the Story of Baldwin Diesel

Locomotives by Gary and Stephen Dolzall, Kalmbach Books, 1984.

- Train Shed Cyclopedia

n°60, Newton K.

Gregg, 1977.

- Diesel Locomotives,

Cyclopedia volume 2, compiled by Bob

Hyden, Kalmbach Books, 1980.

- La traction

électrique et diesel-électrique,

Pierre PATIN, collection des chemins de fer aux éditions

Léon Eyrolles, 1952.

- The well-known baldwin railfan website "The

Baldwin Diesel Zone"

- What's going on with the 62029:

"Maintenance"

- The point of view of the DRS 6-4-660 which was

conceived as a export-only model for France.

- An american point of view of what the Baldwin at the

french railways became.

- A well-known website

with a lot of pictures of diesel-electric Baldwin locomotives when

operating in the US

More

information?